TCXT Tubular Magnetic Separator

Product Description

The machine is mainly used to remove the magnetic metal impurities in the raw materials. It is suitable for feed, grain, and oil processing factories.

1. Cylinder of stainless steel, iron rate>98%, except by the latest rare-earth permanent magnetic material, magnetic strength ≥3000 gauss.

2. Installation convenience, flexibility, do not take a field.

3. Strengthen emboldening type, completely prevent door hinge magnetic door straining phenomenon.

4. Equipment without any power, convenience in maintenance. Long life service.

Technical Parameters

Main technical parameter for TXCT series:

|

Model |

TCXT20 |

TCXT25 |

TCXT30 |

TCXT40 |

|

Capacity |

20—35 |

35—50 |

45—70 |

55—80 |

|

Weight |

98 |

115 |

138 |

150 |

|

Size |

Φ300*740 |

Φ400*740 |

Φ480*850 |

Φ540*920 |

|

Magnetism |

≥3500GS |

|||

|

Iron Removal Rate |

≥98% |

|||

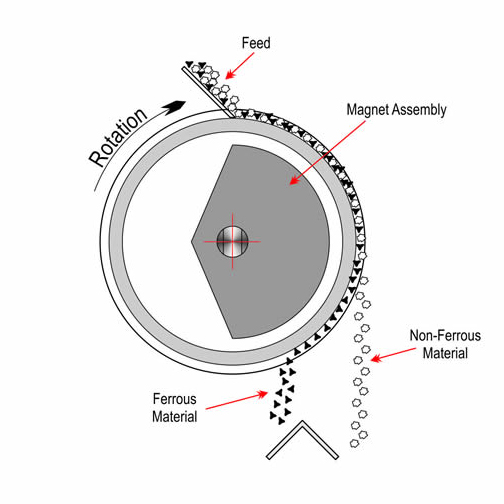

Working Principle

These powerful magnetic separators are widely used in the food and pharmaceutical industries to remove ferrous metal contamination from dry free flowing products such as sugar, grains, tea, coffee and plastics. They are designed to attract and retain any ferrous particles present in the product stream.

The working principle of a magnetic separator involves the use of high-strength magnets arranged in a housing or tubular structure. The product flows through the housing and any ferrous particles present in the product are attracted to the magnet surface. The magnetic field is designed to be strong enough to trap ferrous particles, but not strong enough to affect product quality or consistency.

The captured ferrous particles are then held on the surface of the magnet until the magnet is removed from the housing, allowing the particles to fall into a separate collection container. The efficiency of a magnetic separator depends on factors such as the strength of the magnet, the size of the product flow, and the level of iron contamination present in the product.