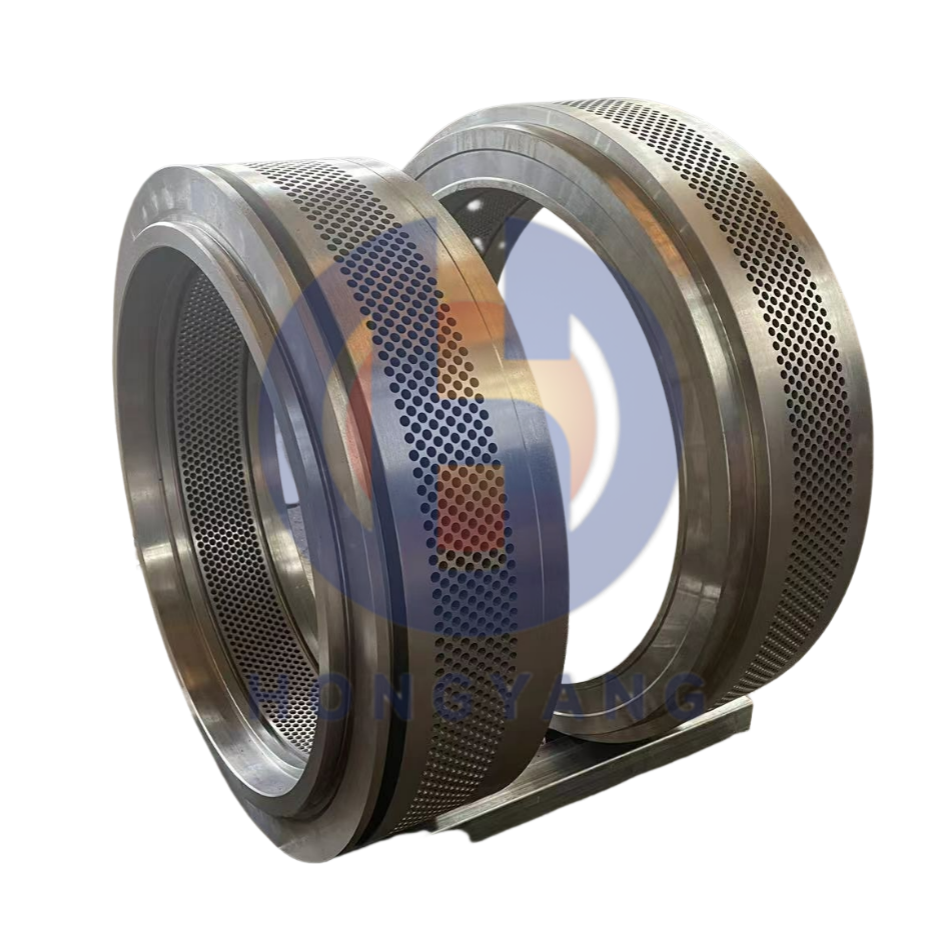

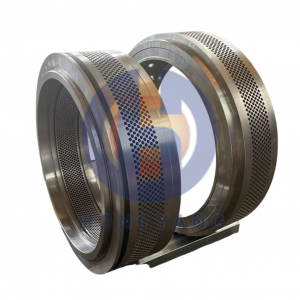

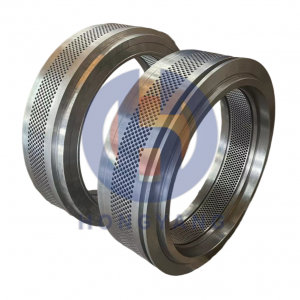

Stainless Steel Ring Dies – Durable Replacement Parts for Feed Pellet Mills

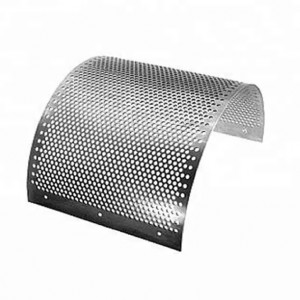

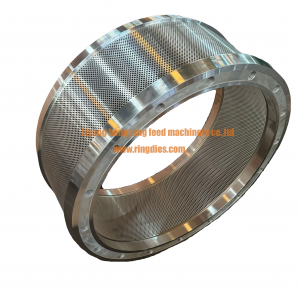

Pellet mill ring dies are an essential component in the production of high-quality pellets for animal feed, wood pellets for heating, and other industrial applications. These dies are typically made from high-strength and durable materials, such as carbon steel or stainless steel, and are designed to withstand the high pressures and heat generated during the pelletization process.

The design of the pellet mill ring die is also vital to ensure consistent and efficient production of pellets. The holes or channels in the ring die are carefully designed to ensure that the feedstock is compressed and shaped into pellets of a specific size and density. Properly designed and well-maintained ring dies can significantly improve the quality and efficiency of pellet production, reducing waste and increasing profitability.

Pellet mill ring dies come in a wide range of sizes and hole patterns to accommodate different types of feedstock and pellet sizes. Our ring dies are manufactured using advanced technology and high-quality materials to ensure optimal performance and longevity. They are designed to be easy to install and maintain, and we offer a wide range of replacement parts and accessories to keep your pellet mill running smoothly.

Investing in high-quality pellet mill ring dies will not only improve the quality and consistency of your pellets but also increase the overall efficiency and profitability of your operation.