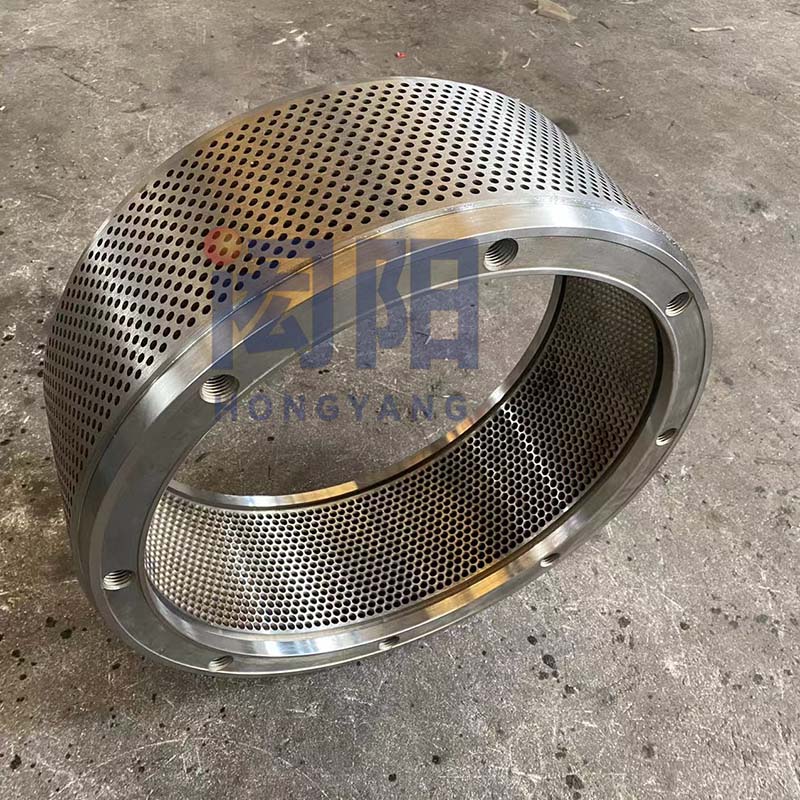

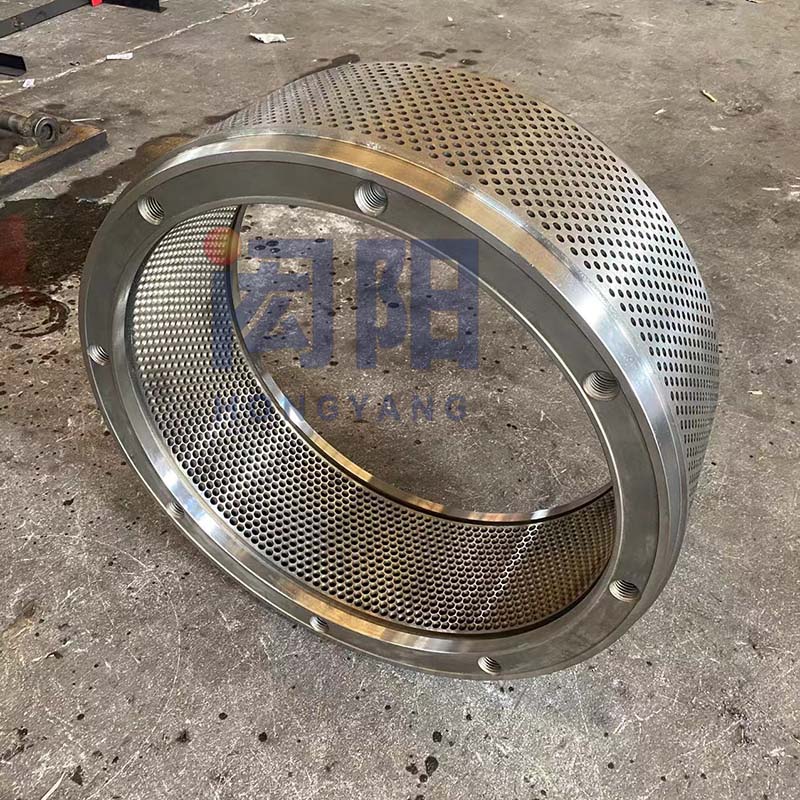

Ring Die YEMMAK520 For Pellet Machine

Product Description

When it comes to pellet production, pellet ring dies are an essential part of the process. If you are in the pellet production industry, you probably already know that ring dies are responsible for shaping the raw materials into pellets. It is a circular metal ring with many holes of different sizes through which materials such as wood, corn, or fodder are squeezed into pellets.

Product Storage

1. The ring die must be stored in a clean, dry, and ventilated place, and have a good specification mark. If stored in a humid place, it may cause corrosion to the ring die, which may reduce its service life or affect the discharge effect.

2. If the ring die is not used for a long time, it is recommended to coat a layer of waste oil on the surface of the ring die to prevent water corrosion in the air.

3. When the ring die is stored for more than 6 months, the internal oil should be replaced. If the storage time is too long, the material inside will harden, and the granulator can not press it out when it is used again, thus causing a blockage.

Our Advantages

Our professional engineering team will always be ready to serve you with consultation and feedback. We can provide you with free product testing. We will do our best to provide you with the best service and goods. If you are interested in our products, please send us an email or give us a quick call. To learn more about our products and company, you can come to visit our factory. We will generally welcome guests from all over the world to do business with our company and establish business relationships with us. Please feel free to talk to our small business and we are confident that we will share the best trading experience with all merchants.