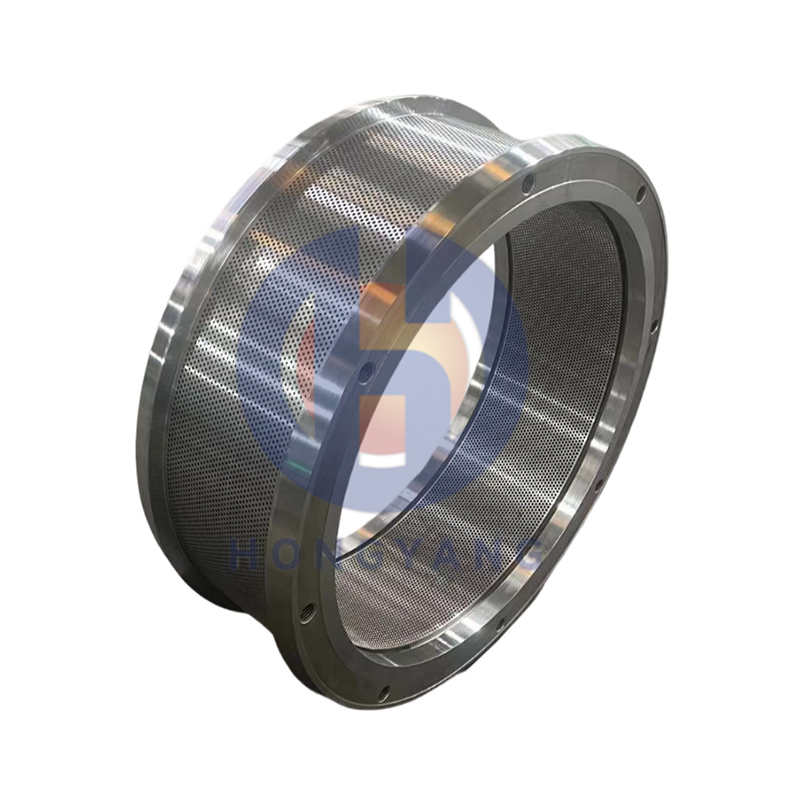

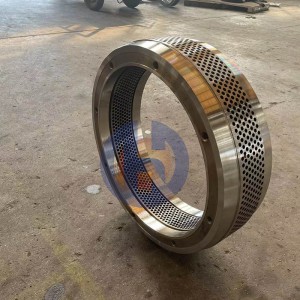

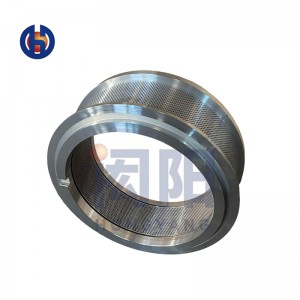

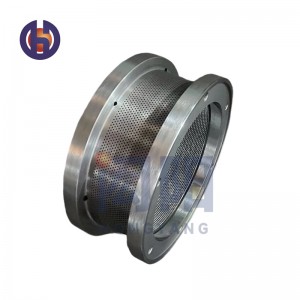

Ring Die Awila420 Pellet Die Awila 420

Product Information

Pellet mills are the machinery used to process raw materials into pellets. These pellets are an efficient energy source and are commonly used in heating systems and power plants. The ring die is a critical component of a pellet mill, responsible for shaping the raw materials into pellets.

The design of the ring die directly affects the yield and quality of the pellets produced. Passage patterns and dimensions in ring die design are critical in determining particle size and shape. With the correct pass pattern, users can produce pellets of different sizes and shapes according to their needs. Therefore, it is important to ensure that you get a ring die with a pass pattern optimized for the type of pellets you are producing.

With the right ring die, users can achieve higher pellet density, which means more pellets can be packed into storage spaces. Additionally, denser and smoother pellets consume less energy when it comes to transportation, which results in lower transportation costs. With this, your pellets will have fewer damages and breakage during transportation, ensuring that you get paid for every bag shipped.

Product Package

1. Usually, the ring die will be wrapped well in waterproof plastic film.

2. The ring die is placed in wooden cases or fixed on pallets (as per customers' request), and then loaded into the containers.

3. Standard exporting package, safe and stable, which is suitable for long-distance transport.

Product Display

We can provide different kinds of ring dies. We can customize the size and shape for you according to your drawing.