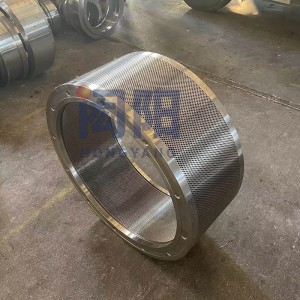

Pellet Ring Die Andritz PM615

Product Information

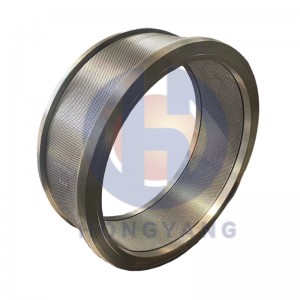

PM615 / PM717 / PM919 RING DIE

Our ring die products have the following characteristics:

1. Selecting high-quality degassed steel billets for external refining.

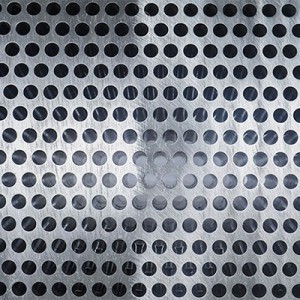

2. Using imported gun drills and multi-station group drills, the mold holes are formed at one time. High smoothness, beautiful appearance, high output, smooth discharge and good particle formation.

3. American vacuum furnace and continuous quenching furnace processing technology, with uniform quenching, good surface finish, and high hardness, ensuring double service life.

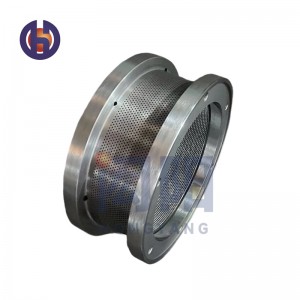

Hole Drilling

◎ Advanced fully automatic four-axis and eight-axis CNC gun drills machines are used in the processing of the die holes.

◎ The die holes are drilled to precise dimensions and spacing to ensure consistent and uniform pellet quality.

◎ High rotating speed, imported tools and coolant ensure the required process conditions for drilling.

◎ The roughness of the machined die holes is small, which guarantees the pelletizing yield and quality.

The hole drilling process is critical in ensuring the overall effectiveness and reliability of the pelletizing system. By drilling holes to the highest possible degree of precision, we can produce high-quality pellets that meet the strictest industry standards, resulting in greater customer satisfaction and increased profitability.

Our Company

In 2006, our company was established and dedicated to producing ring dies. Our company is now in the mature stage of technology, and uses CNC five-axis tire mold gun drill machine, four-head gun drill, CNC ring dies chamfering machine and other equipment for production. Our dies are used to produce chicken, duck, fish, shrimp, wood chips, composite materials, etc. The basic model is: 200-1210; Various models of dies such as Zhengchang, Shepherd, Shende, CPM, OGM, etc. can be customized.

For more than ten years, our company has been committed to the production and research of ring dies. With our technical advantages and the principle of quality responsibility, we are deeply trusted by our customers.