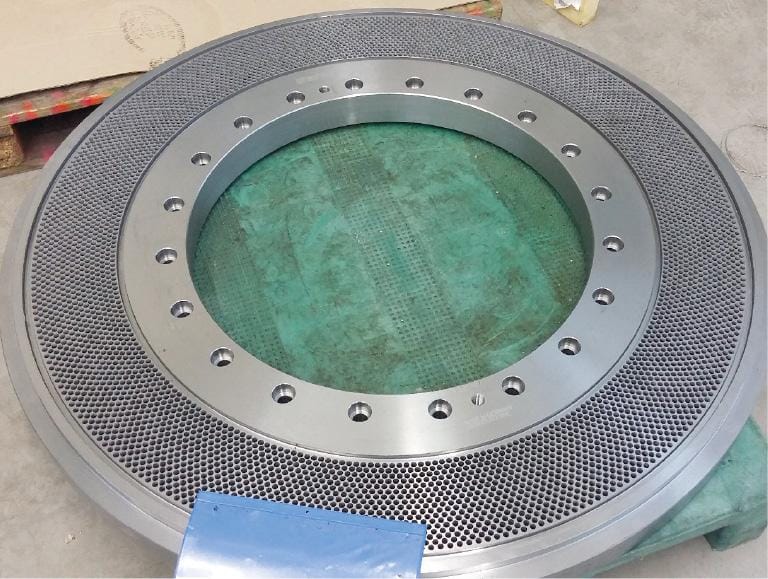

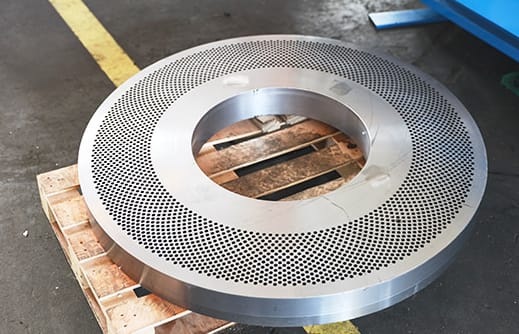

Pellet Mill Flat Die

Product Features

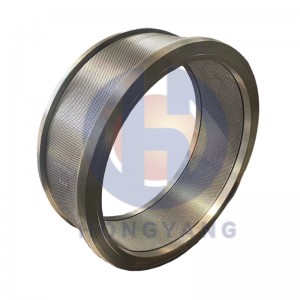

For KAHL pellet mill (Flat die): KAHL38-780, KAHL37-850, KAHL45-1250, etc.

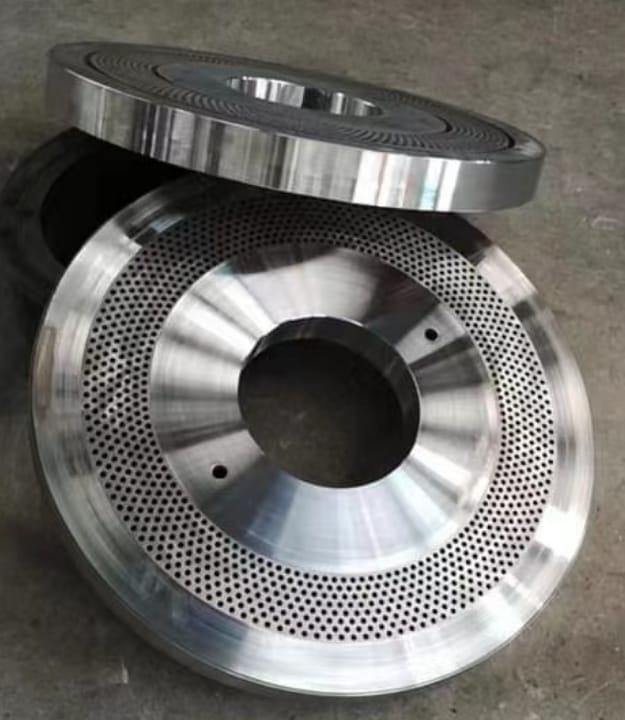

1. Material of ring die: X46Cr13/4Cr13 (stainless steel), 20MnCr5/20CrMnTi (alloy steel) or customized

2. Ring die hardness: HRC54-60.

3. The diameter of the ring die can be: 1.0 mm up to 28 mm

4. The type of particle die can be: annular mold or flat die

5. The outer diameter can be as high as 1800 mm

Product Information

A pellet mill flat die is one of the key parts of a pellet mill. It is a disc with holes in it that the raw material is forced through under high pressure to produce pellets. The holes in the flat die determine the size and shape of the pellets. Here are some key points about a pellet mill flat die:

1. A pellet mill flat die is made of high wear-resistant materials such as steel or alloy steel because it handles abrasive materials under high pressure.

2. The flat die has multiple holes of a specific diameter. As the pellet mill's rollers push materials through the die holes, they are shaped into pellets with the desired size.

3. The flat die design and the number of holes can vary depending on the pellet mill size and capacity. Large pellet mills may have multiple flat dies working together.

4. The flat die rotates at a high speed and works together with roller assemblies that compress the material through the die holes.

5. The flat die needs to be maintained and replaced periodically due to wear from high pressure and abrasion. Sharper holes in the die help to cut the materials and produce good-quality pellets.