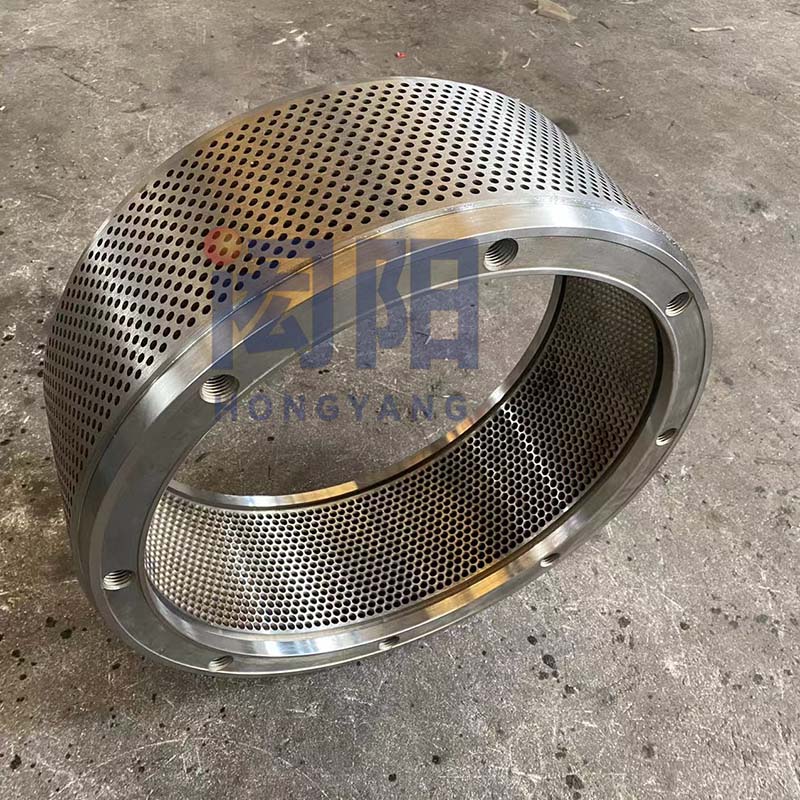

Pellet Mill Die PTN580 Ring Die

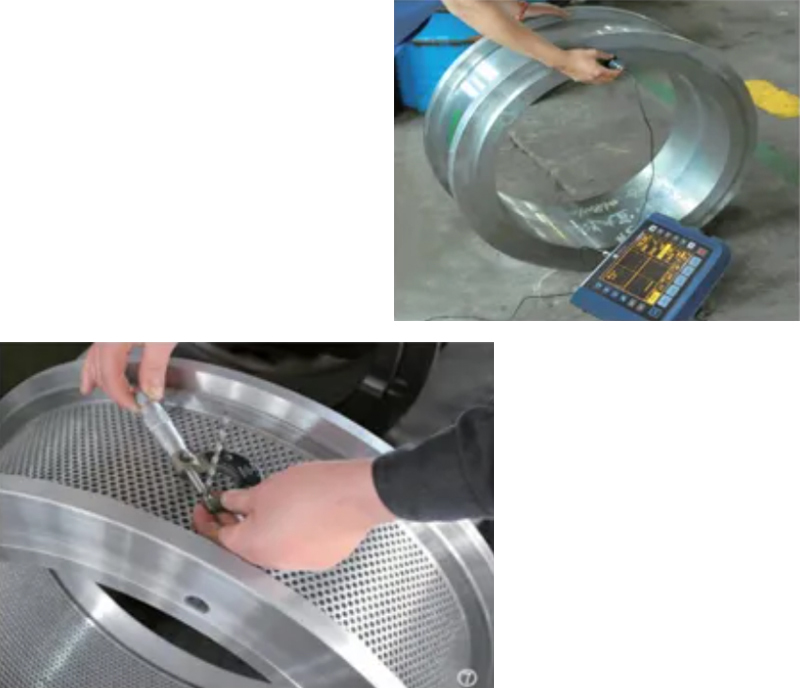

Product Inspection

1. 100% ultrasonic flaw detection, strictly control the quality of the blank source;

2. 100% hardness testing, controlling the tempering quality of ring die forgings, improving the cutting addition, refining the grain structure, and ensuring the quality of pellets.

3. Check the diameter of the ring dies. The diameter of the ring die should be accurate and consistent to ensure the uniformity of the produced particles.

4. Check the ring die holes. Ensure the smoothness of the ring die holes.

5. Check the surface finish: the surface finish of the ring die should be smooth and free of defects. Any rough spots or sharp edges can damage the biomass material and affect pellet quality.

By checking the quality of your pellet mill ring dies from raw materials to the finished products, we can ensure that you can consistently produce high-quality pellets with our products that will surely meet your specific requirements.

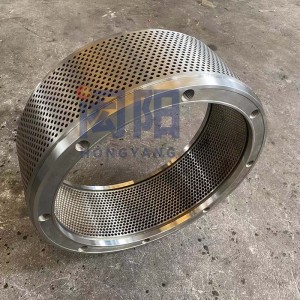

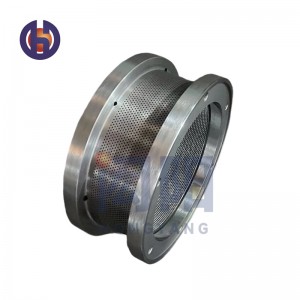

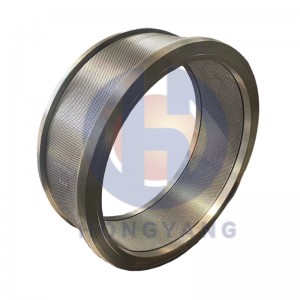

Product Display

About Us

Since 2006, our company has been dedicated to the production of ring molds as a professional manufacturer. The molds produced are suitable for chicken, duck, fish, shrimp, wood chips, and composite materials. Our company is equipped with CNC five-axis tire mold gun drilling machines, four-head gun drilling machines, and CNC ring mold chamfering machines.

Our products have won an excellent reputation in each of the related nations. Our qualified R&D engineers will be there to provide you with consulting services and we will do our best to meet your requirements. Therefore, please feel free to contact us for consultation. We will definitely give you the best quotation and after-sales service.