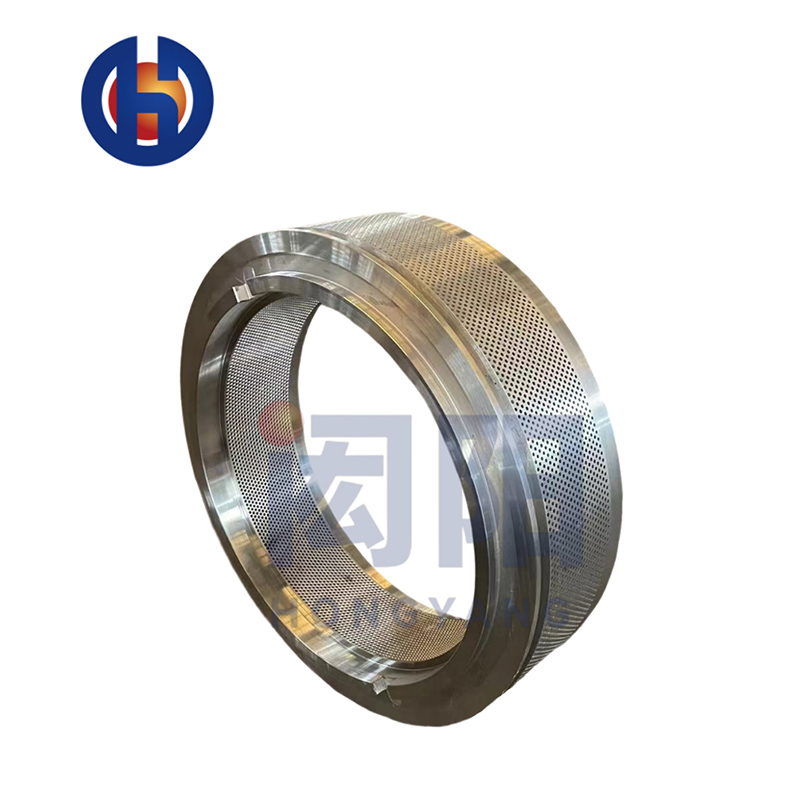

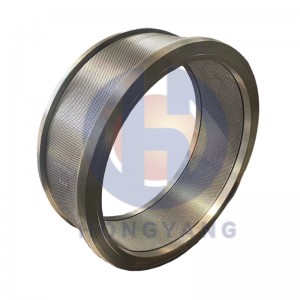

OGM Ring Die Spare Parts For Pellet Mill

Product Description

For OGM pellet mill: OGM-0.8, OGM-1.5, OGM-6, etc.

According to customer requirements or corresponding drawings, we can process ring die with different models and different apertures.

The ring die hole has good surface finish, good granulation forming, good particle appearance finish, few cracks, neat material shape, reduced particle powder content, smooth discharge and high output. The production efficiency of the same specification is significantly higher than that of the peers.

The high smoothness of the hole wall of the ring die feed hole reduces the resistance of the material entering the mold hole, which is beneficial to improve the granulation yield of the material through the improvement of the material: the angle of the ring die feed hole is uniform, ensuring the good uniformity of the ring die discharge.

To ensure the quality and service life of the ring die, the difference between the hardness values of 46Cr13 ring die HRC52-55 and other parts shall not be greater than HRC2.

The ring die is heated at high temperature (1050 °) and quenched by rapid cooling. During this process, the die body will have a slight deformation of 0.3~1.0mm. The concentricity error of the ring die can reach 0.05~0.15m through grinding.

Product Display

Our Strengths