1. Formula of the Feed

The common Feed Raw Materials are Corn, Soybean Meal, Wheat, Barley, Additives and so on. The highest quality Feed can be made with a reasonable materials’ Ratio. As the customers of Hongyang, we will provide you with the Feed Formula for reference.

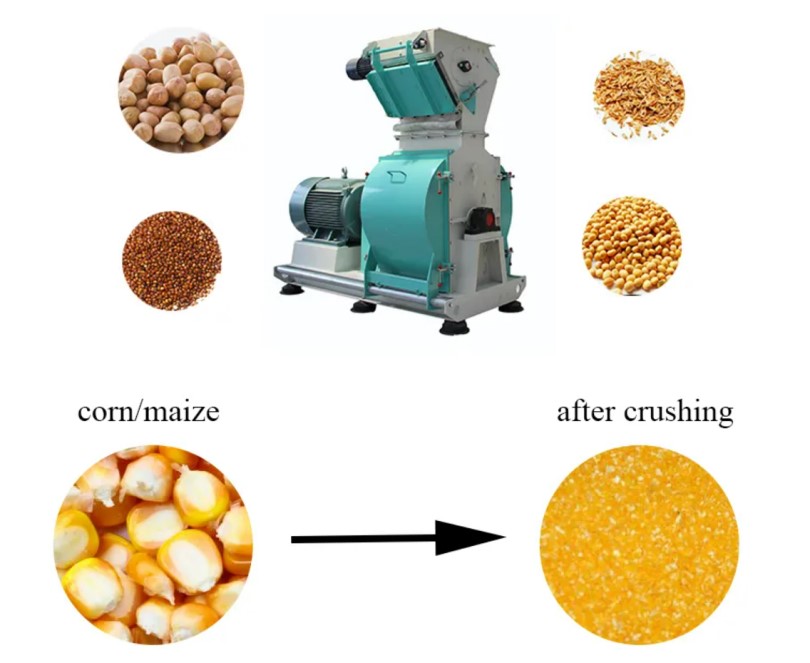

2. Raw Material Particle Size

It is generally believed that Reducing the Particle Size of raw material is beneficial to particle quality. However, in order to avoid the waste of electricity and the decline of productivity, excessive Crushing is not recommended. Instead, a suboptimal particle size is recommended. Hongyang SFSP series Hammer Mill can not only realize three kinds of crushing granularity, but also save energy consumption.

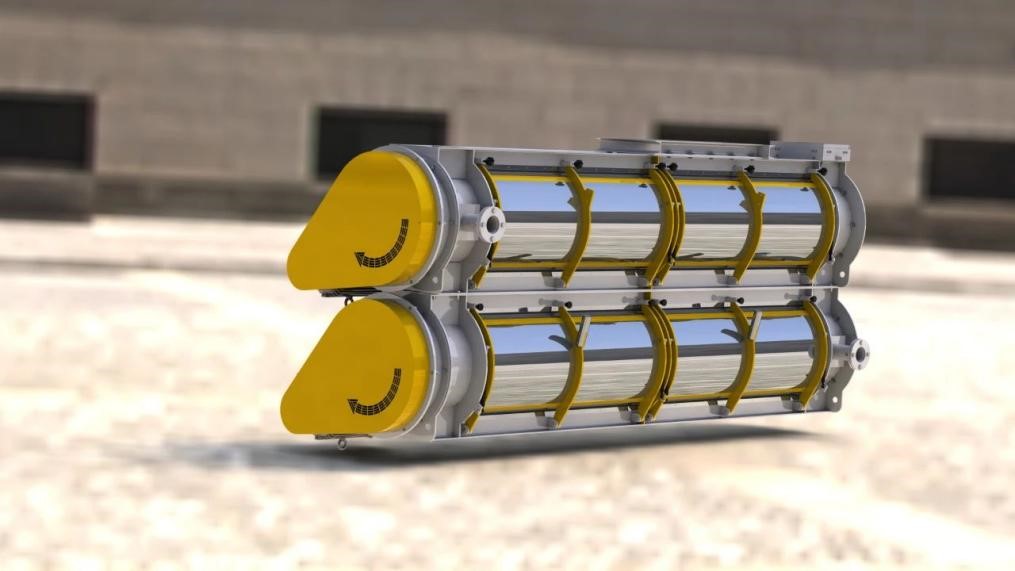

3. Steam Conditions

When the powder feed enters the Conditioner, it will receive high pressure steam treatment. The steam provides heat and water for starch gelatinization, particle adhesion, predigestion, and pathogen destruction. The temperature and processing time of the steam in the tuner are the main factors affecting the particle durability. When the temperature exceeds 80° C, the high quality granular material can be produced, and the shortest processing time is 30 seconds. The particle density can be increased by prolonging the quenching and tempering time to 3-4 minutes. Hongyang conditioner is filled with thermal insulation rock wool, which has better thermal insulation performance, more energy saving and better quality.

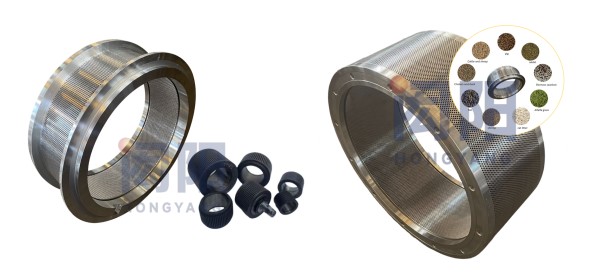

4. Specification of Ring Die/Pellet Press Die

Thicker die to improve the quality of pellets, because of the increased feed pellets and the friction between the die wall, also raised the rate of starch gelatinization. However, using thicker or aperture thin die can reduce productivity. In addition, the distance between rollers and the die increased from 0.1 mm to 2 mm, can improve the durability of the pellets.

The ring die/pellet press die quality of Hongyang Feed Machinery is better, more durable, and has higher production capacity. We recommend and customize the most suitable compression ratio and aperture for customers.

5. Cooling

When leaving the conditioner, the temperature of pellet feed is 70-90°C and the moisture content is 15-17%. During cooling, the particle temperature should be reduced to 5°C above room temperature, and the moisture should be reduced to 12%. Rapid cooling causes the moisture and heat on the surface of the particles to be lower than that inside the particles, resulting in fragile particles. However, prolonged cooling time will lead to overdrying of particles, increase of wear rate and decrease of palatability. Hongyang countercurrent cooler uses the countercurrent cooling principle to cool the particles with high temperature and high humidity, avoiding the sudden cooling caused by the direct contact between the cold air and the hot material, so it can effectively prevent the particles from surface cracking.

More information for Feed and Organic Fertilizer Industry, pls check from the below:

Website: www.ringdies.com

Or contact with us directly:

Phone: +86 18912316448

E-mail: hongyangringdie@outlook.com

Post time: Aug-31-2023