Particle hardness is one of the quality indicators that every feed company pays great attention to. In livestock and poultry feeds, high hardness will cause poor palatability, reduce feed intake, and even cause oral ulcers in suckling pigs. However, if the hardness is low, the powder content will increase. The low hardness of large, especially medium and large pig and medium duck pellet poultry feed will cause unfavorable quality factors such as feed grading. How to ensure that the feed hardness meets the quality standards? The hardness of a feed product, in addition to the adjustment of the feed formula, the production of feed The processing technology has a crucial impact on the hardness of pellet feed.

1. The influence of grinding process on particle hardness.

The factor that plays a decisive role in the particle hardness in the grinding process is the grinding particle size of the raw materials: Generally speaking, the finer the grinding particle size of the raw materials, the easier it is for starch to gelatinize during the conditioning process, and the stronger the bonding effect in the pellets. The harder it is to break, the greater the hardness. In actual production, the crushing particle size requirements should be appropriately adjusted according to the production performance of different animals and the size of the ring die aperture.

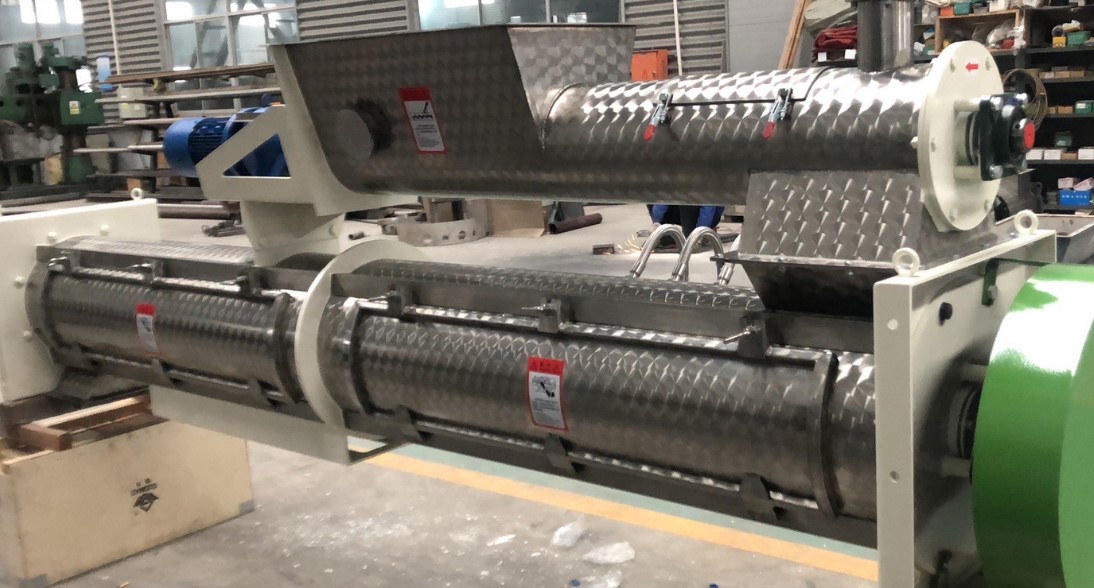

2. The influence of puffing process on particle hardness

Through the puffing treatment of raw materials, toxins in the raw materials can be removed, bacteria can be killed, harmful substances can be eliminated, the proteins in the raw materials can be denatured, and the starch can be fully gelatinized. At present, puffed raw materials are mainly used in the production of high-grade suckling pig feed and special aquatic product feed. For special aquatic products, after the raw materials are puffed, the degree of starch gelatinization increases and the hardness of the formed particles also increases, which is beneficial to improving the stability of the particles in water. For suckling pig feed, the particles are required to be crispy and not too hard, which is beneficial to the feeding of suckling pigs. However, due to the high degree of starch gelatinization in puffed suckling pig pellets, the hardness of the feed pellets is also relatively large.

3. Add the impact of the oil injection process on feed hardness.

The mixing of raw materials can improve the uniformity of various particle size components, which is beneficial to keeping the particle hardness basically consistent and improving product quality. In the production of hard pellet feed, adding 1% to 2% moisture in the mixer will help improve the stability and hardness of the pellet feed. However, the increase in moisture brings negative effects to the drying and cooling of the particles. It is also not conducive to product storage. In the production of wet pellet feed, up to 20% to 30% moisture can be added to the powder. It is easier to add about 10% moisture during the mixing process than during the conditioning process. The granules formed from high-moisture-moisture materials have low hardness, are wet and soft, and have good palatability. This kind of wet pellet feed can be used in large-scale breeding enterprises. Wet pellets are generally difficult to store and are generally required to be fed immediately after production. Adding oil during the mixing process is a commonly used oil adding process in feed production workshops. Adding 1% to 2% of grease has little effect on reducing the hardness of the particles, while adding 3% to 4% of grease can significantly reduce the hardness of the particles.

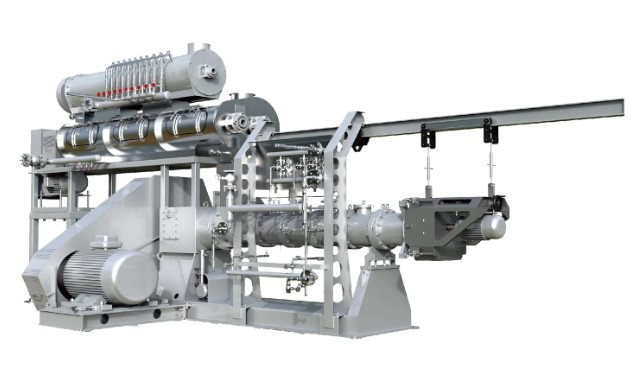

4. Effect of steam conditioning on particle hardness.

Steam conditioning is a key process in pellet feed processing, and the conditioning effect directly affects the internal structure and appearance quality of the pellets. Steam quality and conditioning time are two important factors that affect the conditioning effect. High-quality dry and saturated steam can provide more heat to increase the temperature of the material and gelatinize the starch. The longer the conditioning time, the higher the degree of starch gelatinization. The higher the value, the denser the particle structure after forming, the better the stability, and the greater the hardness. For fish feed, double-layer or multi-layer jackets are generally used for conditioning to increase the conditioning temperature and extend the conditioning time. It is more conducive to improving the stability of fish feed particles in water, and the hardness of the particles also increases accordingly.

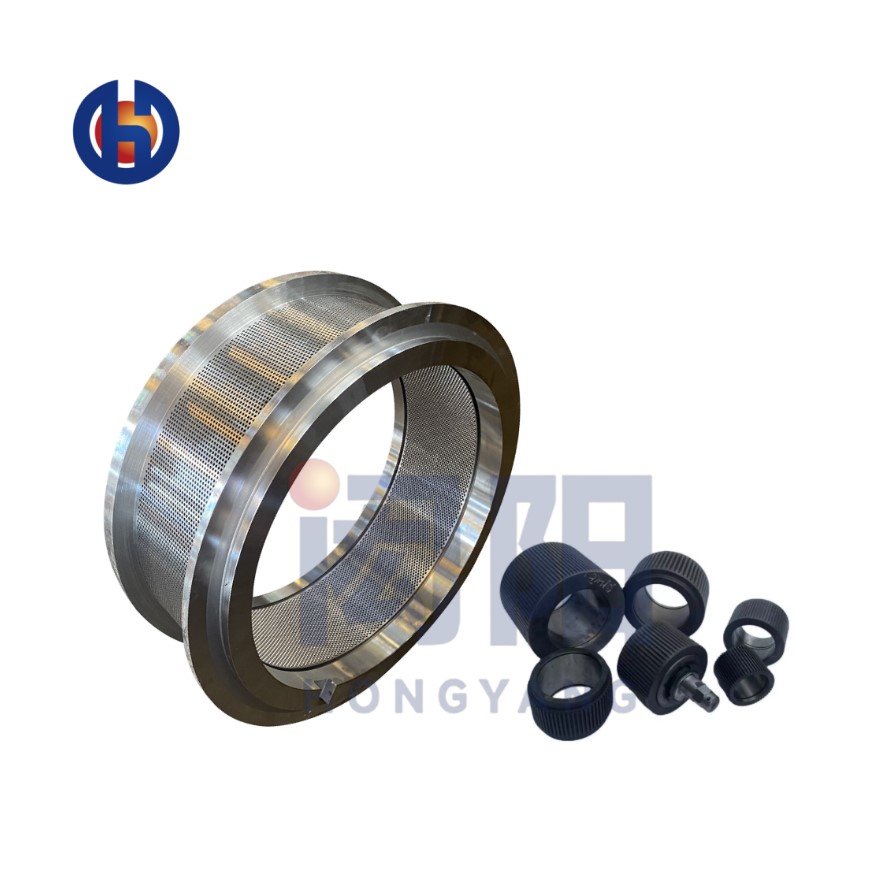

5. The influence of ring die on particle hardness.

Technical parameters such as the aperture and compression ratio of the ring die of the feed pellet mill affect the hardness of the pellets. The hardness of the pellets formed by ring dies with the same aperture but different compression ratios increases significantly as the compression ratio increases. Selecting a suitable compression ratio ring die can produce particles of suitable hardness. The length of the particles has a significant impact on the pressure-bearing capacity of the particles. For particles of the same diameter, if the particles have no defects, the longer the particle length, the greater the measured hardness. Adjusting the position of the cutter to maintain an appropriate particle length can keep the hardness of the particles basically consistent. The particle diameter and cross-sectional shape also have a certain impact on particle hardness. In addition, the material of the ring die also has a certain impact on the appearance quality and hardness of the pellets. There are obvious differences between the pellet feed produced by ordinary steel ring dies and stainless steel ring dies.

6. The influence of post-spraying process on particle hardness.

In order to extend the storage time of feed products and improve product quality within a certain period of time, necessary drying and cooling processing of feed particles is required. In the test of measuring the hardness of particles, by measuring the hardness of the particles for the same product multiple times with different cooling times, it was found that particles with low hardness are not significantly affected by the cooling time, while particles with larger hardness increase with the cooling time. As the time increases, the particle hardness decreases. This may be because as the water inside the particles is lost, the brittleness of the particles increases, affecting the particle hardness. At the same time, after the particles were rapidly cooled with large air volume and slowly cooled with small air volume, it was found that the hardness of the former was lower than that of the latter, and the surface cracks of the particles increased. It is also worth mentioning that crushing large hard particles into small particles can significantly reduce the hardness of the particles.

Post time: Mar-14-2024