1. With the advent of the antibiotic-free era, heat-sensitive substances such as probiotics are gradually added to pellet feeds. As a result, during the feed production process, temperature will also have a very important impact on the quality of pellet feeds. If the temperature is too high during the production of pellet feed, it will kill heat-sensitive substances such as probiotics. If the temperature is too low, the bacterial substances in the pellet feed will not be completely sterilized, resulting in the production of pellet feed. The quality is substandard. Therefore, in order to avoid the influence of temperature on the test, this test is to study the influence of tempering temperature and die hole aspect ratio on the processing quality of pellet feed under low temperature conditions, so as to study the production of pellets of pellet feed under corresponding conditions after the raw materials are matured. Whether it is full and whether it meets the standards for particle quality testing. The main purpose of this experiment is to provide certain theoretical guidance for the production of livestock pellet feed.

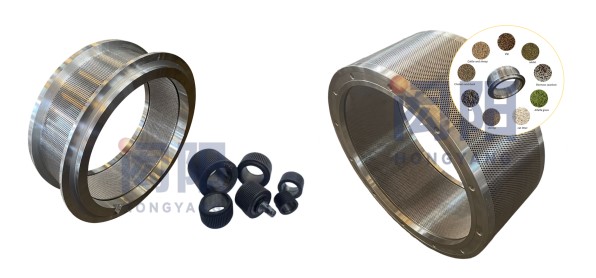

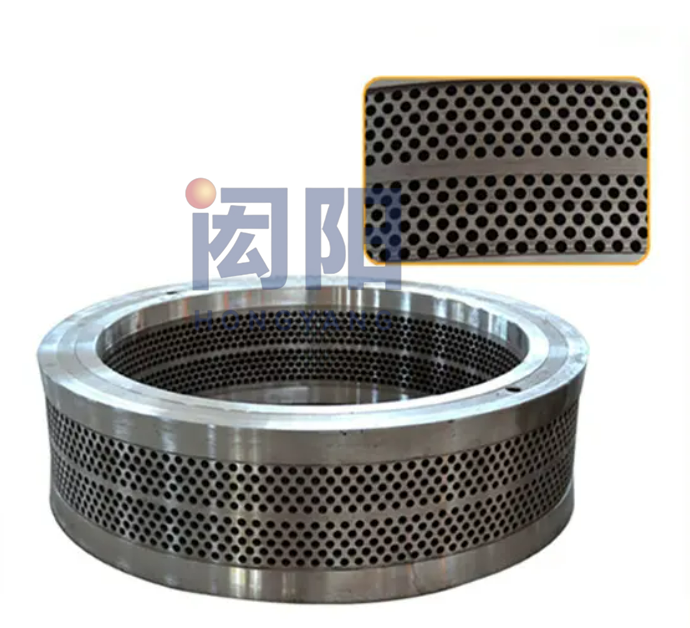

2.1 The main ingredients of the experimental diet and pellet raw materials include: corn, fish meal, salt, methionine, threonine, etc. The corn needs to be crushed into 11.0mm fine particles, and then the raw materials are proportioned according to the nutritional requirements, and then matured. After cooling, heat-sensitive substances such as probiotics are added, and finally tempered into particles. The temperatures of conditioned feed pellets are generally 60, 50, 40, and 30°C, and the length and diameter of the die holes are generally 7:1, 6:2, and 10:1, and 300 mg/kg of probiotic substances are added based on the test materials. , and the temperature of the pellet feed also needs to be tempered to protect the activity of probiotics. In addition, some vitamins must be added to each kilogram of pellet feed to ensure that the nutritional elements of the pellet feed can meet the national feed requirements.

2.2 Sampling and collecting samples

In order to ensure that the pellet feed produced is qualified, after the pellet feed is produced, it is necessary to randomly select the pellet feed for quality inspection.

2.3 Standards and methods of quality inspection

2.3.1 Gelatinization degree of starch

When testing the gelatinization degree of starch in pellet feed samples, the staff can use amylase to detect it. Add amylase to starch, and calculate the chemical reaction between amylase and starch. Finally, add iodine solution, and judge the degree of starch gelatinization by observing the color depth of the chemical reaction result.

2.3.2 Hardness of feed pellets

In order to test the quality of pellet feed, its hardness also needs to be tested. The hardness standard of pellet feed should refer to relevant information.

2.3.3 Tolerance index of pellet feed

Put the pellet feed into the rotary box and rotate it at 50r/min for 20 minutes. After stopping, take out the pellet feed and then weigh the remaining mass of the pellet feed and express it in m.

3. test results

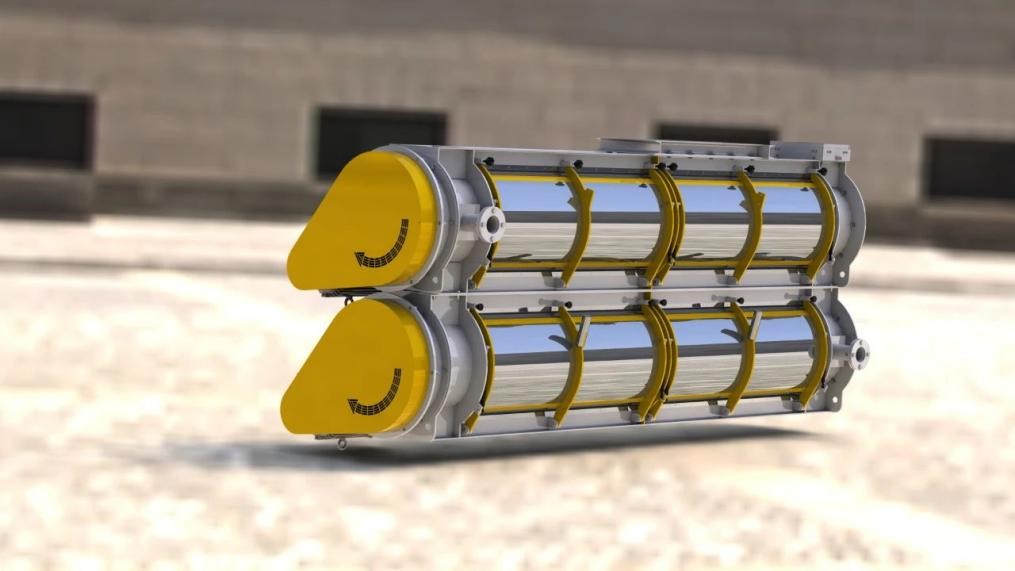

3.1 The influence of feed quality, temperature and hole diameter ratio on the quality and hardness of pellet feed. This experiment mainly studies the change pattern of pellet feed quality under low temperature conditions. The main raw materials include corn, soybean meal, etc., which are processed and matured. After that, it is then granulated at low temperatures. It was found that the quality of pellet feed is not only affected by the proportion of raw materials, but also by the diameter of the die hole of the processing machine. When the temperature of producing pellet feed is higher, the ratio to the diameter and length of the membrane hole of the machine is larger, and the hardness of the pellet feed produced is higher, but it will affect the activity of probiotics in the feed, and the power consumed in producing pellet feed will be will also increase accordingly. The test results show that in order to ensure that the quality of the pellet feed produced reaches the standard, it needs to be produced under such production conditions.

3.2 The influence of conditioning temperature and die hole diameter on the gelatinization degree of starch in pellet feed. After a series of experimental studies, it was found that the mechanical conditioning temperature and die hole diameter have a very important impact on the starch gelatinization degree of pellet feed. Under the same temperature conditions, the smaller the diameter of the die hole, the greater the impact on the gelatinization degree of starch in the pellet feed.

3.3 The influence of tempering temperature and die hole diameter to length ratio on the retention degree of probiotics in the granules. After a series of experiments, it was found that the activity of probiotics is greatly affected by temperature. If the temperature is too high during the production of pellet feed, it will directly reduce the activity of probiotics. Therefore, in order to ensure the retention of probiotics during the production process of pellet feed and the quality testing standards of pellet feed, it is necessary to produce pellet feed under low temperature conditions.

4. Conclusion

Through this test, it can be found that the quality, hardness and number of probiotics in pellet feed are not only affected by the production temperature, but also by the diameter of the die hole. Through a series of studies, it was found that using mature raw materials for the production of pellet feed under low temperature conditions is conducive to improving the quality and hardness of pellet feed; under the same temperature conditions, the higher the die hole diameter ratio, the better the production of pellets. The energy consumed in the feeding process is higher. Through experiments, it was found that the optimal solution for producing pellet feed is to use equipment with a die hole diameter ratio of 6:1 at a temperature of 65°C to produce pellet feed of the highest quality.

Post time: Jan-10-2024