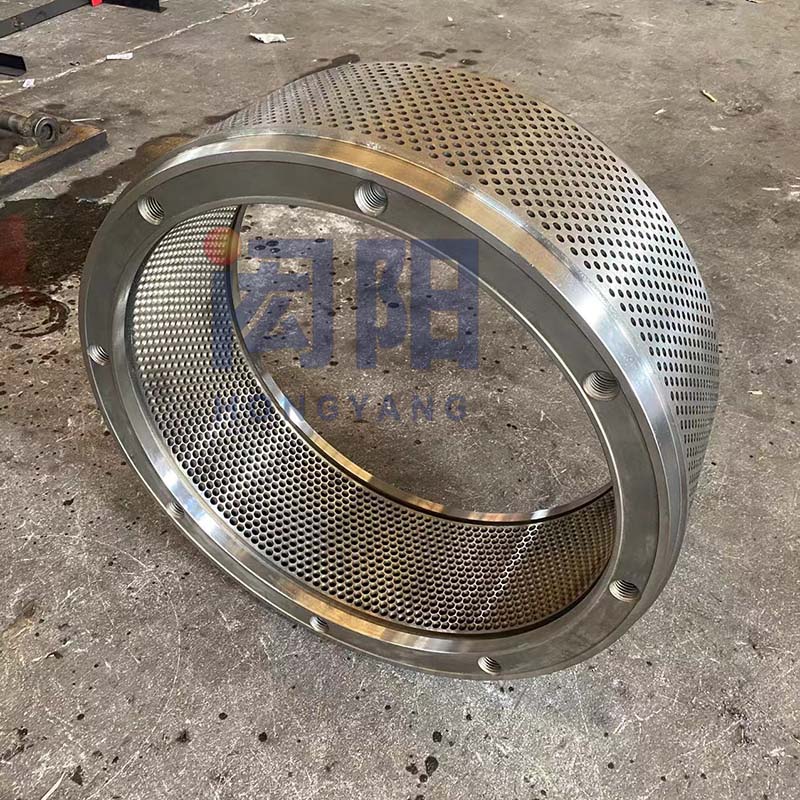

Matrix Andritz PM717 Ring Die

Product Information

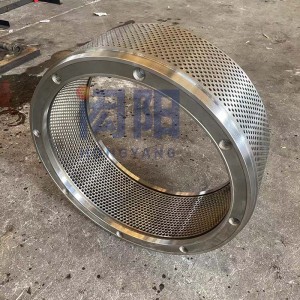

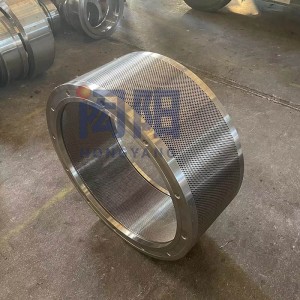

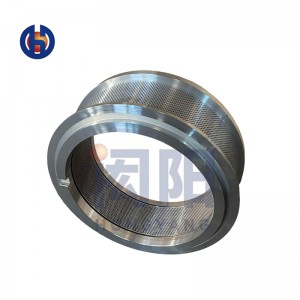

CE Approved Hot Sale Ring Die Of Feed Pellet Production Line

Technological Requirements

1 Select quality forging stock, but general companies select casting stock

2 Use gun drill, the hole is completed by one time, nice appearance, high capacity

3 Use America vacuum oven and advanced treatment craft, ensure twice service life

4 Strong R&D help customer design compression ratio and strength according to requirements, Ensure pelleting effect and high quality of product

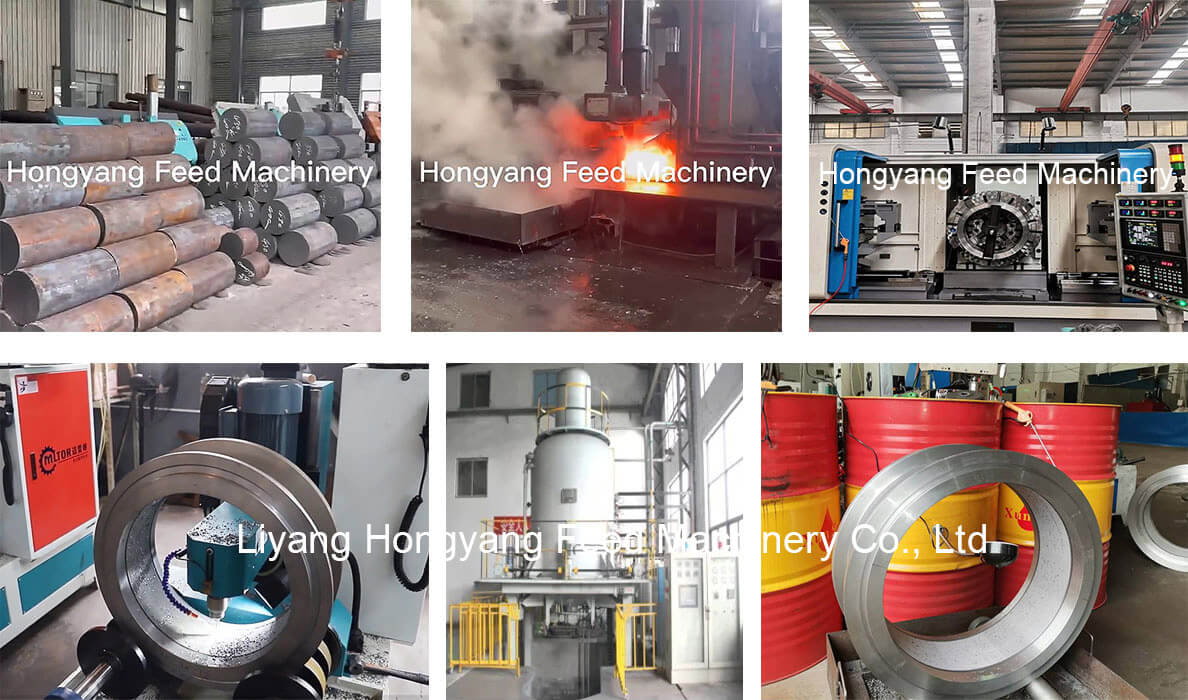

Production Process

We are a direct factory with high quality, high capacity, competitive price, and fast delivery. We are able to do all the die-making processes from raw material selection to the finished product. Here I also show you some pictures of the process of how to make a feed pellet ring die ( from beginning to finishing).

The manufacturing process of pellet ring die generally includes the following steps:

Selection of raw materials: The main material for manufacturing pellet ring dies is steel, usually high-grade alloy steel. The type of steel selected for the mold depends on the required durability, wear, and heat resistance.

Processing blank: The steel is forged and molded into a blank of the desired shape and size, and then lathed to remove any rough surfaces and sharp edges.

Drilling and countersinking: Fully automatic CNC gun drills and countersink machines create high-precision and smooth die holes.

Heat treatment: Vacuum furnaces are used for quenching and tempering the ring die to improve its hardness and strength.

Quality checking: Before the ring die is finalized, quality control professionals conduct a comprehensive inspection of the ring die, such as HRC testing, to ensure that it meets the specified quality standards.