Hammer Blade Crusher Blade For Hammer Mill

Product Information

The hammer blade is commonly used in industrial milling and grinding applications. These blades are designed to impact and break a variety of materials, including grain, minerals, and other materials.

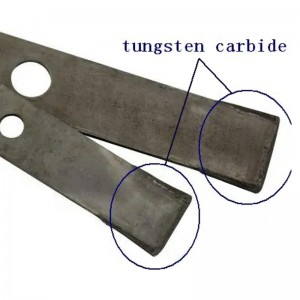

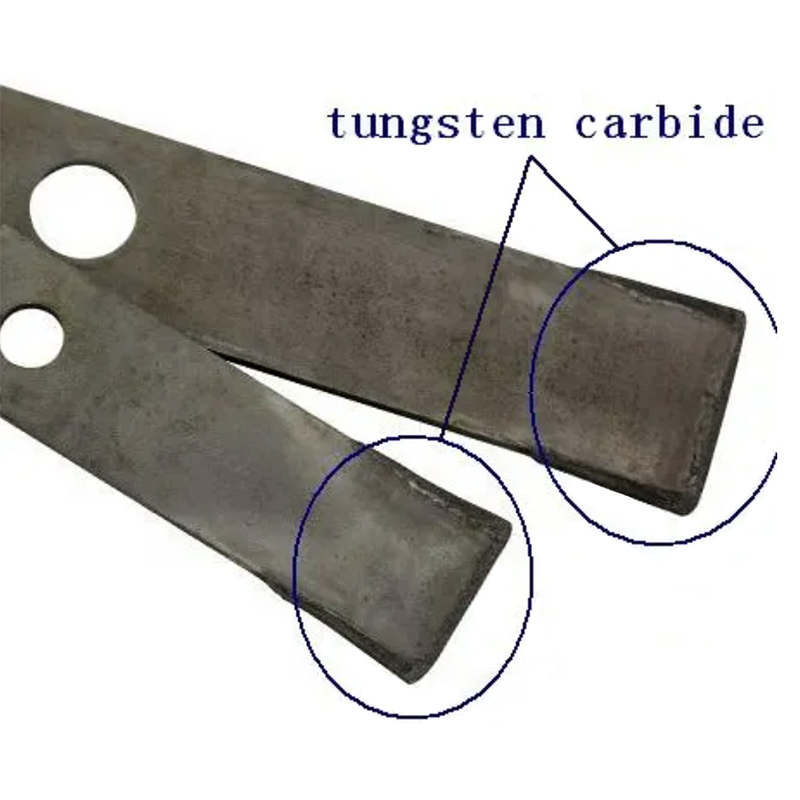

There are various types of hammer blades, based on their shape, size, and configuration, such as tungsten carbide hammer blades, smooth plate hammer blades, and sugar cane hammer blades. The type of hammer blade used depends on the type of material being processed and the desired outcome.

The materials of hammer blade include: low carbon steel, medium carbon steel, special cast iron, etc.

The size and shape of the hammer blade can be customized to suit different applications and materials, allowing for more targeted and efficient milling or grinding.

The hammer blade is the working part of the crusher that directly hits the material, so it is the wearing part with the fastest wear and the most frequent replacement. When the four working angles of the hammer are worn, they should be replaced in time.

Product Features

1. The hammer blades are reinforced by high hardness, high tungsten carbide overlay welding and spray welding, resulting in a better and higher performance.

2. Tungsten carbide hammer blades are highly resistant to corrosion, making them ideal for exposure to wet or chemical environments.

3. Tungsten carbide is one of the hardest materials available, which means that tungsten carbide hammer blades are highly resistant to wear and tear and can withstand heavy use without breaking or being damaged.

4. Tungsten carbide hammers can be used in various jaw crushers, straw crushers, wood crushers, sawdust crushers, dryers, charcoal machines, etc.

Different Hammer Blades

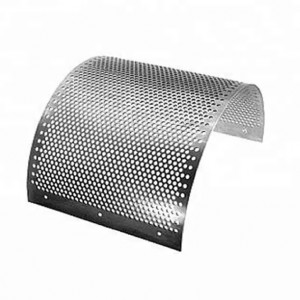

Other Spare Parts