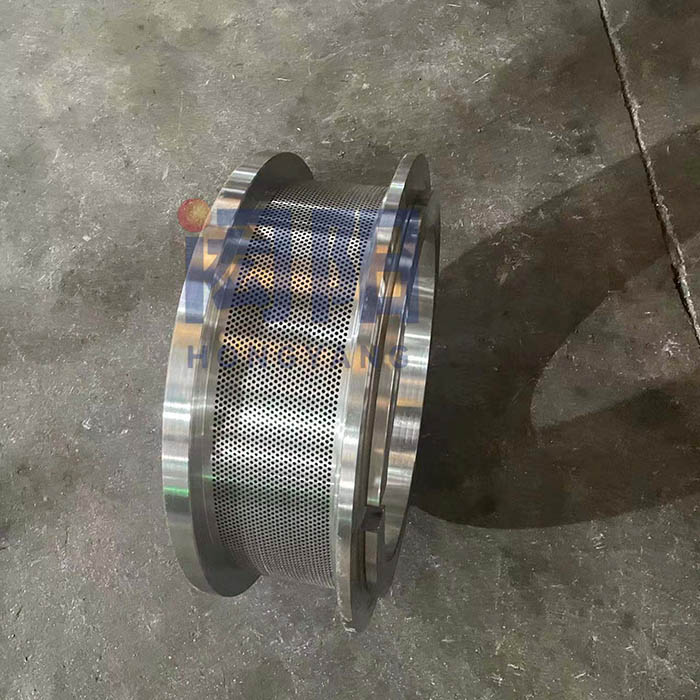

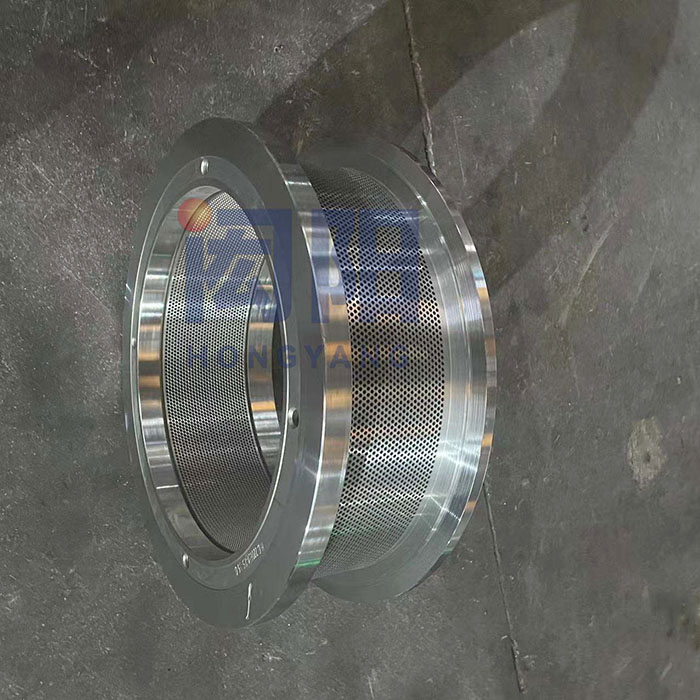

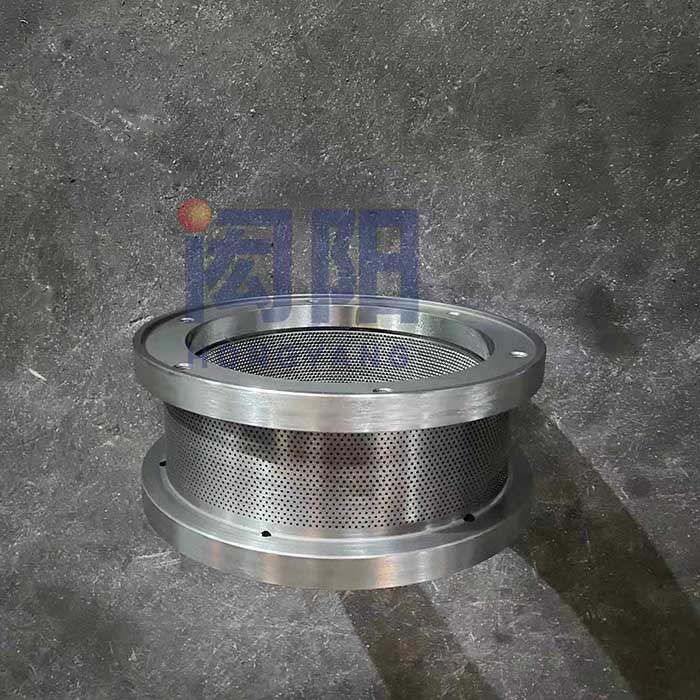

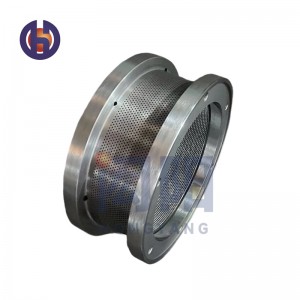

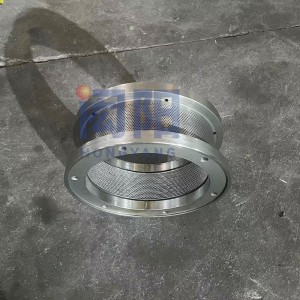

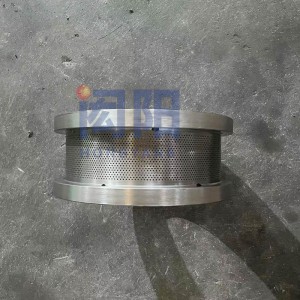

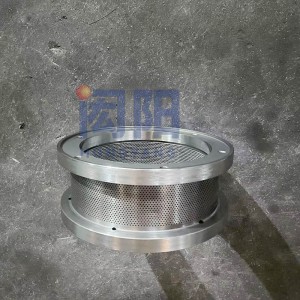

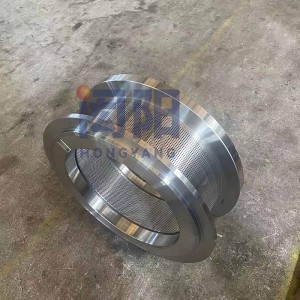

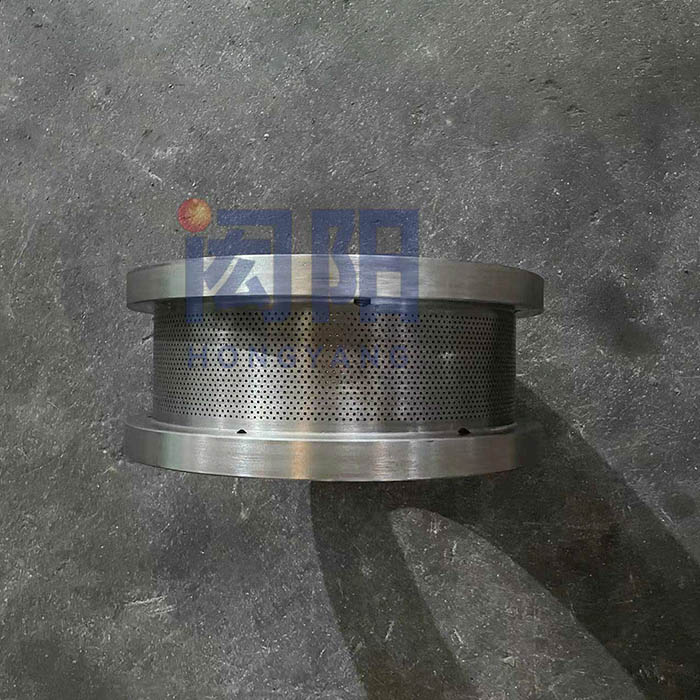

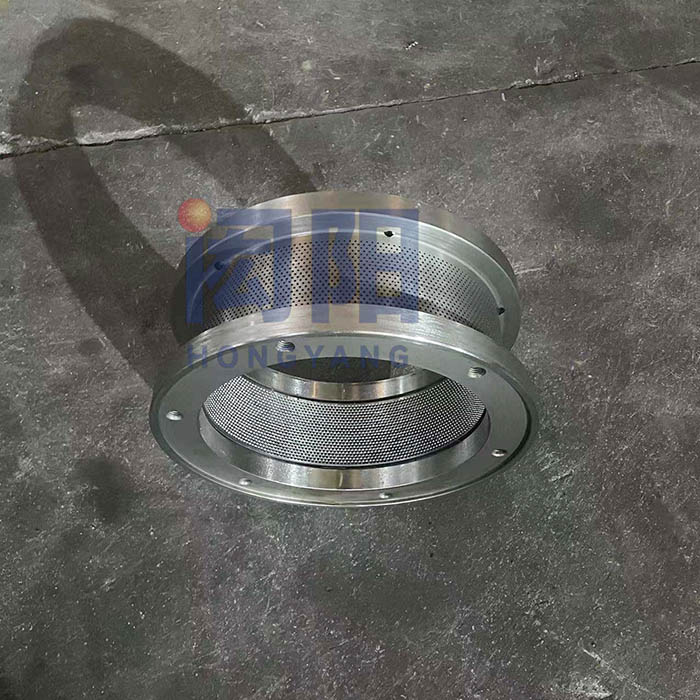

Feed Pellet Ring Die HUAMU HKJ 250

Product Features

1. Select high-quality out-of-furnace refining and degassed billets.

2. The mold adopts imported gun drill and multi-station group drill, the mold hole is formed at one time, the finish is high, the appearance of the produced feed is beautiful, the output is high, the material is discharged smoothly, and the particles are formed well.

3. The mold adopts the combined treatment process of American vacuum furnace and continuous quenching furnace, which has uniform quenching, good surface finish and high hardness, ensuring twice the service life.

Product Display

Since 2006, our company has been committed to the production of professional chemical factories for ring dies. The dies produced are suitable for chicken, duck, fish, shrimp, wood chips, composite materials, etc., and are now in a mature stage of technology. Our company adopts CNC five-axis tire mold gun drill machine, four-head gun drill, CNC ring mold chamfering machine.

The basic models of ring dies manufactured by the company are: 200-600; all types of dies from Zhengchang, Muyang, Shende and CPM can be ordered.

Resolving Blockages

If the ring die is blocked during pellet production, it needs to be removed from the machine and cleaned up.

1. The most common way is to use an electric drill to get the feed clogged in the die hole.

2. If the diameter of the blocked ring die is less than 2.5mm, the ring die can be put in water and heated. The material inside the mold hole will slowly expand and protrude out of the mold hole through the longer time of boiling, so that the material inside the hole becomes loose. After 1 or 2 days of cooking, scrape off the material protruding, then put the ring die on the granulator for grinding, and press out the residual material in the hole.

3. Small aperture ring die clogging can also be used to cook the die with hot oil, so that the material in the die hole at high-temperature coke, becomes smaller, and then clear through. Specific practice: make a metal basin bigger than the ring die, put the ring die into it, add No.15 oil and make it dip over the die surface; heat the oil for about 6-8 hours, until the oil rarely bubbles up.